Business Central: Optipack Guide

Below is a schematic overview of the outbound process of Business Central.

In standard Business Central, the outbound process starts when Sales Orders are created and released for fulfillment. These orders are grouped into Warehouse Shipments, and the warehouse team executes picking and packing operations before posting the shipment. While Business Central supports tracking of item dimensions and weights through Item Attributes or custom fields, there is no built-in cartonization engine that determines how to combine multiple items into the most efficient boxes.

This means that:

- Packing is typically done manually at the packing station, or by following simple static rules (“always use box type A unless item X is present”).

- Item dimensions and weight data are not used to compute optimal box combinations.

- There is no spatial optimization, and packaging material or freight space is often wasted.

This is where OptiPack API comes in. The API can be called after all items and quantities for a shipment are known—that is, once the Warehouse Shipment has been created and its Sales Lines are finalized, but before any Handling Units, package labels, or shipping documents are generated. At this point, the full list of items (with dimensions and weights) can be sent to OptiPack to calculate how these should be best combined into available boxes.

In the remainder of this guide we demonstrate, in a sandbox environment, how we can generate a request (JSON format) and send it to our API. We’ll add different elements to the BC UI to configure the necessary parameters and trigger these optimizations manually. Ideally, these optimizations are of course triggered automatically and results should be persisted in the necessary data tables of BC.

Required API data

Below is a minimal JSON for the /pack endpoint:

1{ 2 "orders": [ 3 { 4 "id": "order_1", 5 "items": [ 6 { 7 "id": "item_1", 8 "width": 1, 9 "height": 1, 10 "depth": 1, 11 "quantity": 4 12 } 13 ] 14 } 15 ], 16 "bins": [ 17 { 18 "id": "bin_1", 19 "width": 1, 20 "height": 1, 21 "depth": 1 22 } 23 ] 24}

It consists of the following pieces of informations:

orders: a list of the orders that must be packed; items of different orders will never be packed onto the samebin.bins: the different bins (HUs) available in the warehouse, with their dimensional information. Many other attributes & constraints are supported as well, for the full list, we refer to our API documentation.

For every order a list of items has to be provided, this contains information such as:

width,height,depth: the three dimensions of every itemquantity: how many of this item were ordered- many other possible constraints & attributes such as its weight, the weight it can carry, allowed orientations, sequence values and many many more. See our API documentation for a complete list.

While the concepts of orders and items (with identifiers and quantities) are known in a standard BC environment, important attributes such as their dimensions as well as information about the box assortment in the warehouse are optional or even missing. However, we’ll see that these elements can quickly be added to BC in the guide below.

BC Data tables

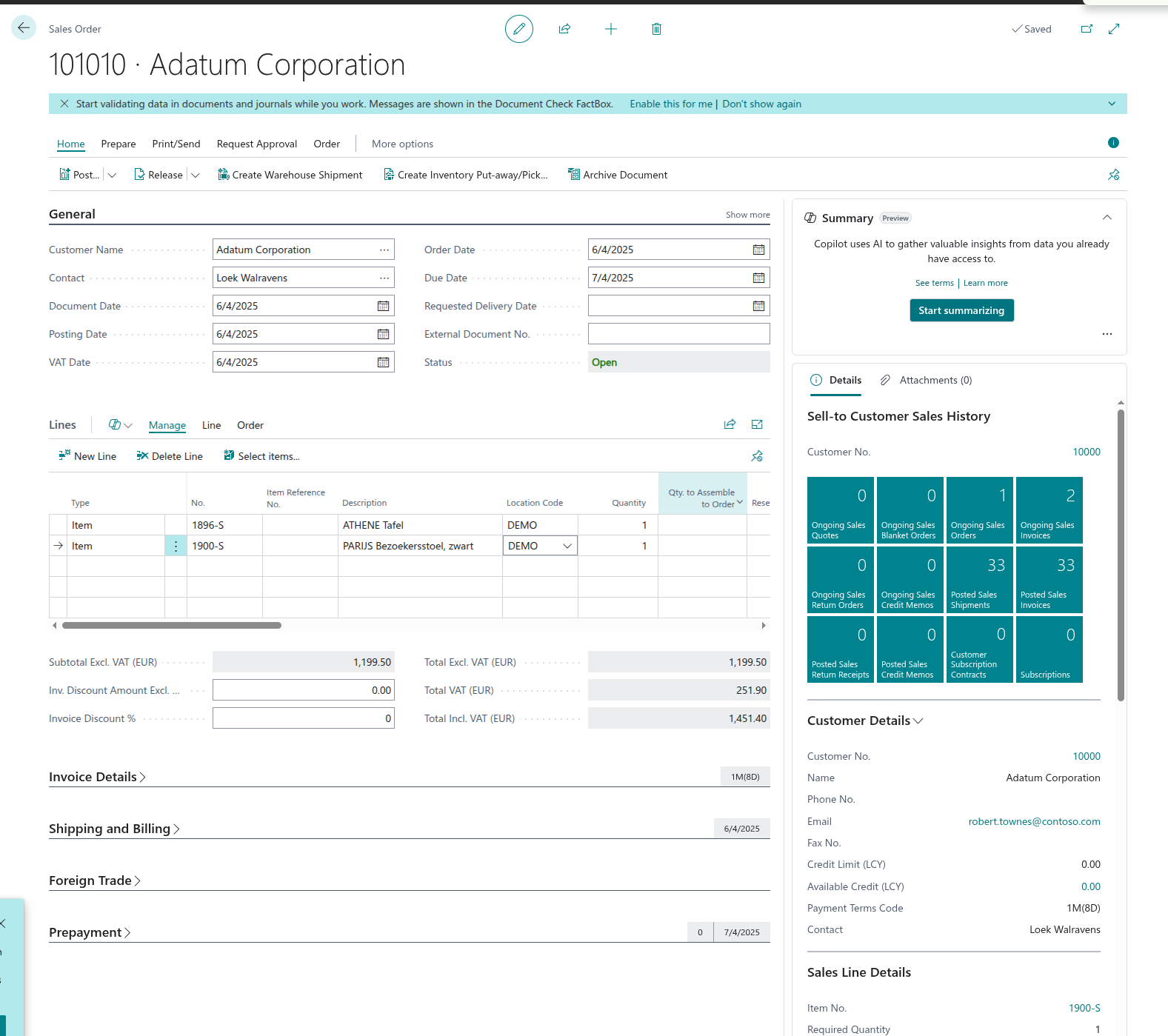

Sales Orders

As depicted in the overview of the introduction, the outbound flow starts with Sales Orders. We will create some ourselves in BC. We can navigate there through ALT + Q > Sales Orders. Once created, we need to make sure to put them in “Released” status so that they can be picked up by the Warehouse Shipments.

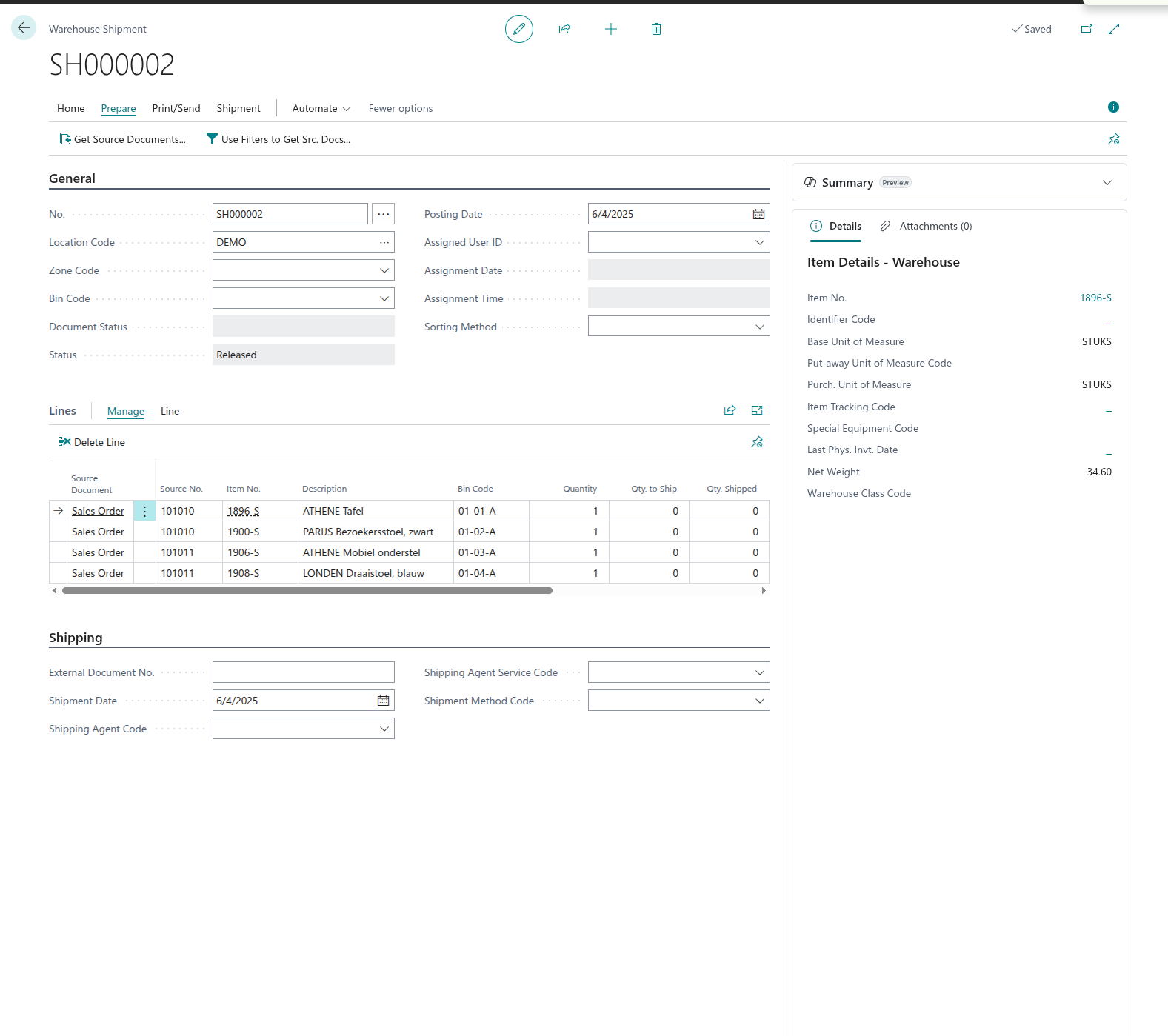

Warehouse Shipments

Once the Sales Orders are created and released, these can be turned into Warehouse Shipments, ready to be picked.

Integrating OptiPack API

Setup

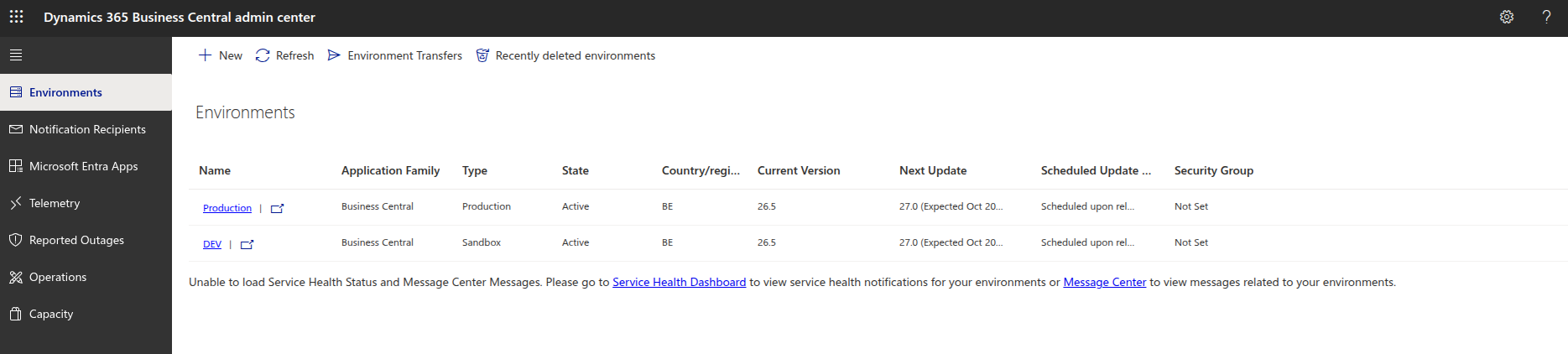

We first create a new environment using the Admin Center which can be accessed through https://businesscentral.dynamics.com/[TENANT_ID]/admin

After creating a new sandbox development environment, we create a new AL project (VSCode has excellent plugins for this) and configure our launch.json and app.json as below:

1{ 2 "id": "<CENSORED>", 3 "name": "OptiPick", 4 "publisher": "Default Publisher", 5 "version": "1.0.0.0", 6 "dependencies": [], 7 "platform": "1.0.0.0", 8 "application": "26.5.38752.38944", 9 "runtime": "15.2", 10 "idRanges": [ 11 { "from": 50100, "to": 50149 } 12 ] 13}

1{ 2 "version": "0.2.0", 3 "configurations": [ 4 { 5 "name": "BC Online", 6 "type": "al", 7 "request": "launch", 8 "server": "https://api.businesscentral.dynamics.com", 9 "environmentName": "DEV", 10 "tenant": "<CENSORED>", 11 "schemaUpdateMode": "Synchronize" 12 } 13 ] 14}

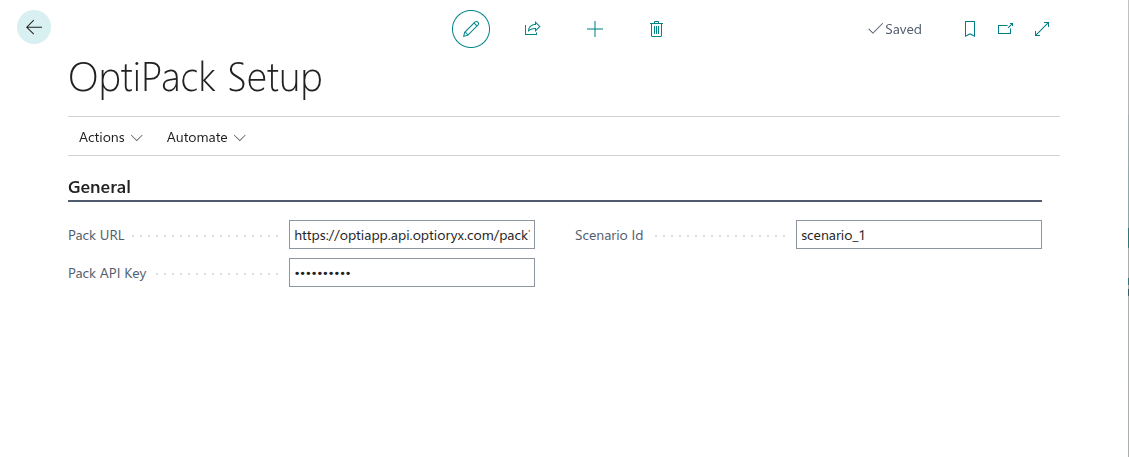

Configuration screen

The first page we’ll be adding to our BC environment allows to configure different parameters for the API such as the endpoint URL, an API key, etc. We’ll create a table and page.

1namespace DefaultPublisher.AL; 2 3table 50122 "OptiPack Setup" 4{ 5 DataClassification = CustomerContent; 6 7 fields 8 { 9 field(1; "Primary Key"; Code[10]) { DataClassification = SystemMetadata; } 10 field(10; "Pack URL"; Text[250]) { InitValue = "https://optiapp.api.optioryx.com/pack?upsert=true&synchronous=true"; } 11 field(20; "Pack API Key"; Text[250]) { ExtendedDatatype = Masked; InitValue = "<CENSORED>"; } 12 field(30; "Scenario Id"; Text[50]) { InitValue = "scenario_1"; } 13 } 14 15 keys { key(PK; "Primary Key") { Clustered = true; } } 16 17 trigger OnInsert() 18 begin 19 if "Primary Key" = '' then 20 "Primary Key" := 'SETUP'; 21 end; 22}

1namespace DefaultPublisher.AL; 2 3page 50123 "OptiPack Setup" 4{ 5 PageType = Card; 6 ApplicationArea = All; 7 UsageCategory = Administration; 8 SourceTable = "OptiPack Setup"; 9 Caption = 'OptiPack Setup'; 10 11 layout 12 { 13 area(content) 14 { 15 group(General) 16 { 17 field("Pack URL"; Rec."Pack URL") { ApplicationArea = All; } 18 field("Pack API Key"; Rec."Pack API Key") { ApplicationArea = All; } 19 field("Scenario Id"; Rec."Scenario Id") { ApplicationArea = All; } 20 } 21 } 22 } 23 24 actions 25 { 26 area(Processing) 27 { 28 action(CreateOrOpen) 29 { 30 Caption = 'Create/Init'; 31 ApplicationArea = All; 32 trigger OnAction() 33 var 34 s: Record "OptiPack Setup"; 35 begin 36 if not s.Get('SETUP') then begin 37 s.Init(); 38 s.Insert(); 39 Message('OptiPack setup created. Fill URL and API key.'); 40 end else 41 Page.Run(Page::"OptiPack Setup", s); 42 end; 43 } 44 } 45 } 46}

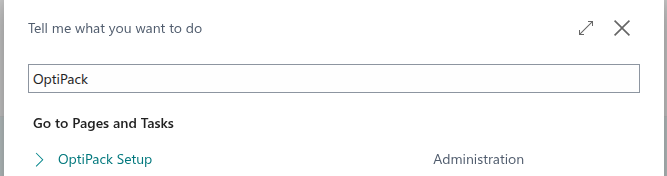

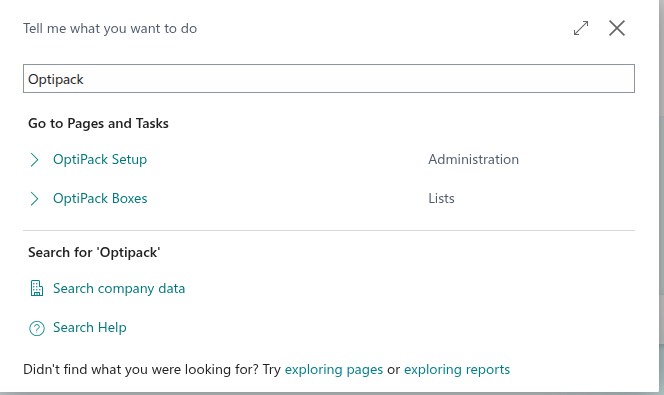

We can navigate to this new page using ALT + Q > OptiPack Setup:

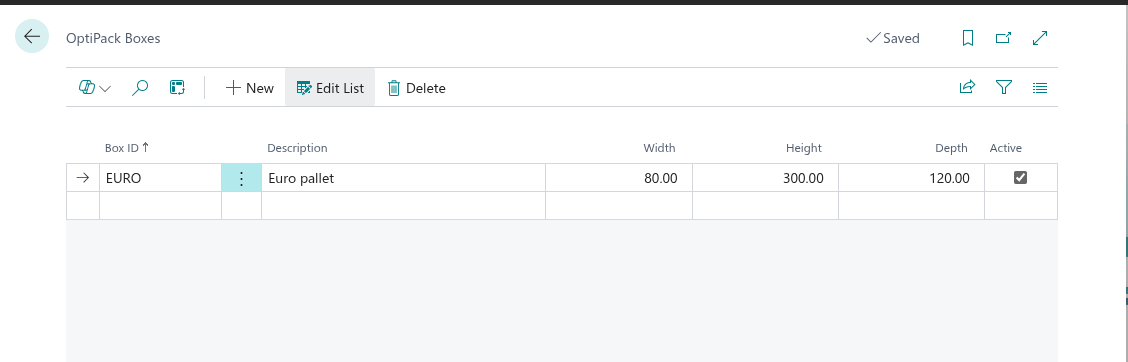

Box management screen

The next graphical element we’ll be adding is a table that allows us to configure the attributes, such as the dimensions, of the different boxes in our warehouse. To keep it minimal, we’ll only allow to configure dimensions, but of course more attributes that can be passed through our API, such as a maximal weight, can be added as well.

1namespace DefaultPublisher.AL; 2 3table 50120 "OptiPack Box" 4{ 5 DataClassification = CustomerContent; 6 7 fields 8 { 9 field(1; Code; Code[20]) { Caption = 'Box ID'; } 10 field(10; Description; Text[100]) { Caption = 'Description'; } 11 field(20; Width; Decimal) { Caption = 'Width'; } 12 field(30; Height; Decimal) { Caption = 'Height'; } 13 field(40; Depth; Decimal) { Caption = 'Depth'; } 14 field(50; Active; Boolean) { Caption = 'Active'; InitValue = true; } 15 } 16 17 keys 18 { 19 key(PK; Code) { Clustered = true; } 20 } 21}

1namespace DefaultPublisher.AL; 2 3page 50121 "OptiPack Boxes" 4{ 5 PageType = List; 6 ApplicationArea = All; 7 UsageCategory = Lists; 8 SourceTable = "OptiPack Box"; 9 Caption = 'OptiPack Boxes'; 10 11 layout 12 { 13 area(content) 14 { 15 repeater(Boxes) 16 { 17 field(Code; Rec.Code) { ApplicationArea = All; } 18 field(Description; Rec.Description) { ApplicationArea = All; } 19 field(Width; Rec.Width) { ApplicationArea = All; } 20 field(Height; Rec.Height) { ApplicationArea = All; } 21 field(Depth; Rec.Depth) { ApplicationArea = All; } 22 field(Active; Rec.Active) { ApplicationArea = All; } 23 } 24 } 25 } 26}

Once created, we can navigate to this page using ALT + Q > OptiPack Boxes:

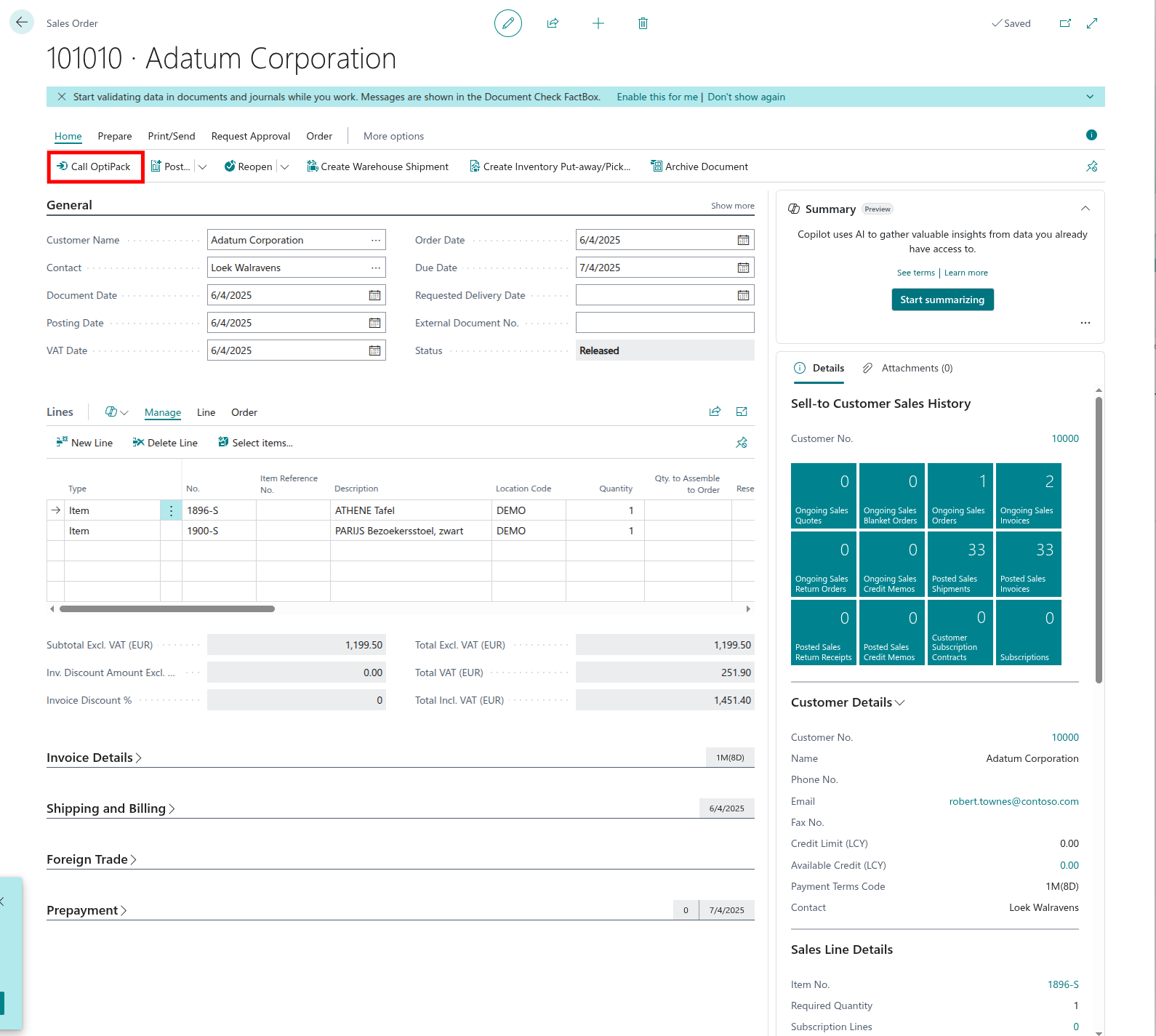

Adding a button to Sales Orders

We’ll extend the Sales Order page of BC to have an extra button that calls our OptiPack API using the ordered items and their quantities. This button can be added to a Warehouse Shipment as well of course.

1pageextension 50133 "SalesOrder_OptiPack" extends "Sales Order" 2{ 3 actions 4 { 5 addlast(Processing) 6 { 7 action(CallOptiPack) 8 { 9 Caption = 'Call OptiPack'; 10 ApplicationArea = All; 11 Promoted = true; 12 PromotedCategory = Process; 13 PromotedIsBig = true; 14 15 trigger OnAction() 16 var 17 Mgt: Codeunit "OptiPack Mgt"; 18 Hdr: Record "Sales Header"; 19 begin 20 Hdr := Rec; // current Sales Order 21 if Hdr."Document Type" <> Hdr."Document Type"::Order then 22 Error('This action works on Sales Orders only.'); 23 24 Mgt.RunForSalesOrder(Hdr); 25 end; 26 } 27 } 28 } 29}

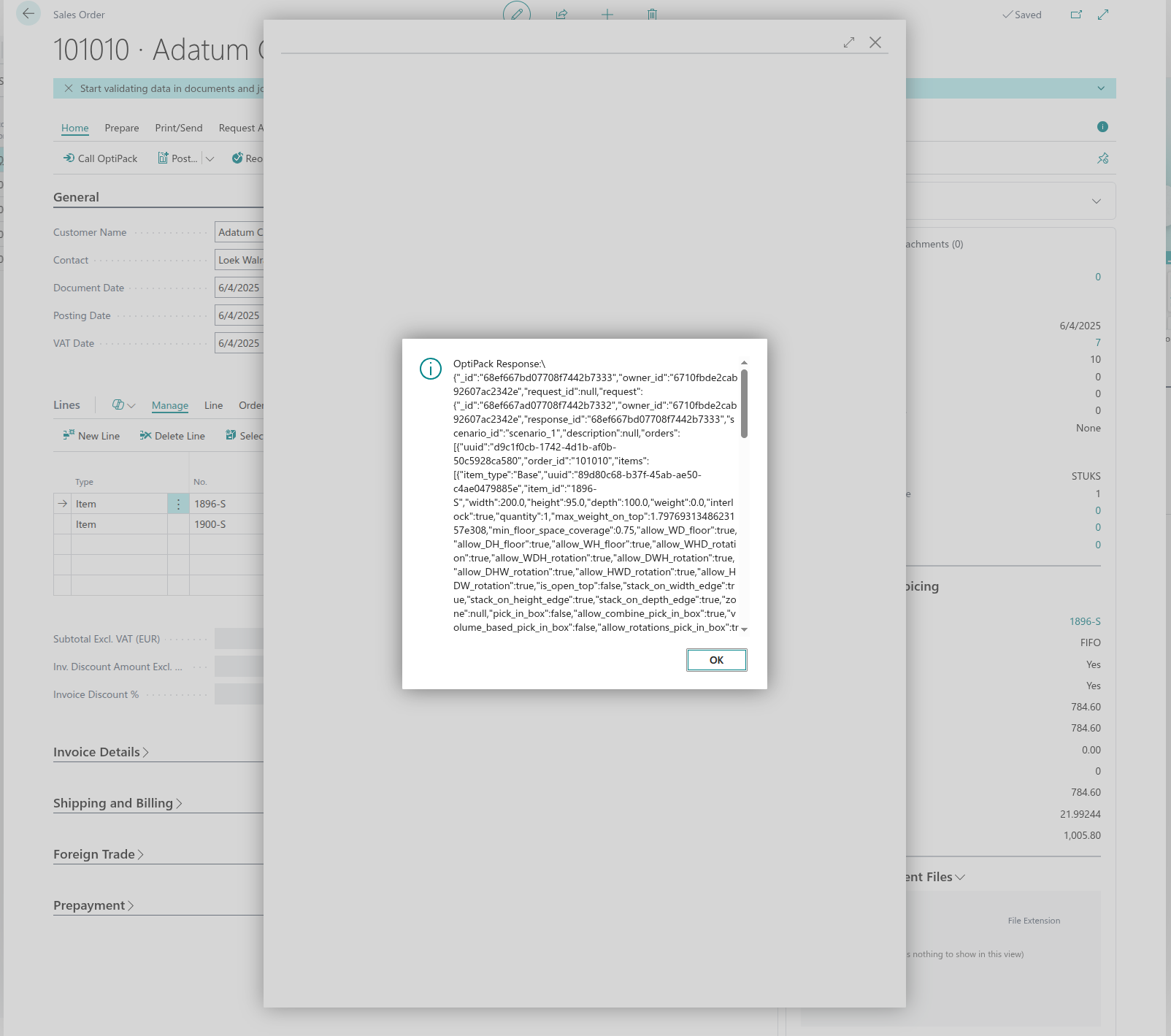

When opening a Sales Order, we’ll now see this button on top:

Define OptiPack result record

We will store the results of our OptiPack API in a data table with the following definition:

1namespace DefaultPublisher.AL; 2 3table 50125 "OptiPack Run" 4{ 5 DataClassification = CustomerContent; 6 7 fields 8 { 9 field(1; "Entry No."; Integer) { AutoIncrement = true; } 10 field(10; "Sales Order No."; Code[20]) { } 11 field(20; "Response Id"; Text[100]) { } 12 field(30; "Created At"; DateTime) { } 13 field(40; "Raw Response"; Blob) { SubType = Memo; } 14 } 15 keys 16 { 17 key(PK; "Entry No.") { Clustered = true; } 18 key(SO; "Sales Order No.") { } 19 } 20}

Calling our API when clicking the button

The largest code file contains the logic to call our OptiPack API. The main procedure is called RunForSalesOrder. After declaring the variables, we check if the configuration screen has been filled in properly, if not we show an error message. Afterwards, we start creating a JsonObject that will serve as our request payload. The request consists of a list or orders OrdersArr, a list of bins BinsArr. Each element in the OrdersArr is an object that contains a list of items to pack ItemsArr. We iterate over all items within the Sales Order from where the button was clicked and try to retrieve attributes with names Width, Height, and Length or in Dutch (the language my sandbox environment was set to) Breedte, Hoogte, Diepte using the TryGetDimFromAttributes sub-procedure. In case any of the dimension attributes is missing, an error is thrown that lists which items miss an essential attribute so that their master data can be fixed. When all dimensions can be retrieved an ItemObj with the identifier, dimensions and quantity is made and added to the ItemsArr. After populating that list, the OrderObj is made using the list of items and an identifier. Finally, we retrieve the content from the Box Management page to create BinObj with an identifier, width, height, length to add to the BinsArr. Afterwards we construct the request by adding a scenario_id, the BinsArr and the OrdersArr to the payload and setting the necessary headers, e.g. a header for the API Key, which is then sent to our API. Finally, we parse the response from our API by creating OptiPack Run records for our data table and using our visualisation endpoint the visualise these results within Business Central.

1namespace DefaultPublisher.AL; 2 3using Microsoft.Sales.Document; 4using Microsoft.Inventory.Item; 5 6codeunit 50132 "OptiPack Mgt" 7{ 8 9 /// Looks up a decimal attribute for an Item No. by any of the candidate names (case-insensitive, EN/NL) 10 local procedure TryGetDimFromAttributes(ItemNo: Code[20]; CandidateNames: array[2] of Text; var OutVal: Decimal): Boolean 11 var 12 ItemAttr: Record Microsoft.Inventory.Item.Attribute."Item Attribute"; 13 ItemAttrValue: Record Microsoft.Inventory.Item.Attribute."Item Attribute Value"; 14 Map: Record Microsoft.Inventory.Item.Attribute."Item Attribute Value Mapping"; 15 NameLower: Text; 16 Cand1Lower: Text; 17 Cand2Lower: Text; 18 ValTxt: Text; 19 IsDecimal: Boolean; 20 begin 21 OutVal := 0; 22 23 // We need mappings for this Item 24 Map.Reset(); 25 Map.SetRange("Table ID", Database::Item); 26 Map.SetRange("No.", ItemNo); 27 if not Map.FindSet() then 28 exit(false); 29 30 // Normalize candidate names to lowercase for matching 31 Cand1Lower := LowerCase(CandidateNames[1]); 32 Cand2Lower := LowerCase(CandidateNames[2]); 33 34 repeat 35 if ItemAttr.Get(Map."Item Attribute ID") then begin 36 NameLower := LowerCase(ItemAttr.Name); 37 38 if (NameLower = Cand1Lower) or (NameLower = Cand2Lower) then begin 39 if ItemAttrValue.Get(Map."Item Attribute ID", Map."Item Attribute Value ID") then begin 40 // Value Type can be Decimal/Text/Option; prefer Decimal/Numeric if present 41 if Evaluate(OutVal, ItemAttrValue.Value) and (OutVal = ItemAttrValue."Numeric Value") then begin 42 OutVal := ItemAttrValue."Numeric Value"; 43 exit(true); 44 end else begin 45 // try to parse the text value 46 ValTxt := ItemAttrValue.Value; 47 if Evaluate(OutVal, ValTxt) then 48 exit(true); 49 end; 50 end; 51 end; 52 end; 53 until Map.Next() = 0; 54 55 exit(false); 56 end; 57 58 procedure RunForSalesOrder(var SalesHdr: Record "Sales Header") 59 var 60 Setup: Record "OptiPack Setup"; 61 Box: Record "OptiPack Box"; 62 SL: Record "Sales Line"; 63 64 // Item Attribute tables (standard) 65 ItemAttr: Record Microsoft.Inventory.Item.Attribute."Item Attribute"; // 7500 66 ItemAttrValue: Record Microsoft.Inventory.Item.Attribute."Item Attribute Value"; // 7501 67 ItemAttrValueMap: Record Microsoft.Inventory.Item.Attribute."Item Attribute Value Mapping"; // 7502 68 69 Http: HttpClient; 70 Resp: HttpResponseMessage; 71 Cnt: HttpContent; 72 ReqHdrs: HttpHeaders; 73 CntHdrs: HttpHeaders; 74 75 Payload: JsonObject; 76 OrdersArr: JsonArray; 77 OrderObj: JsonObject; 78 ItemsArr: JsonArray; 79 ItemObj: JsonObject; 80 BinsArr: JsonArray; 81 BinObj: JsonObject; 82 Root: JsonObject; 83 Tok: JsonToken; 84 ResponseId: Text; 85 86 BodyTxt: Text; 87 MissingTxt: Text; 88 MissingPerItem: Text; 89 W, H, L : Decimal; 90 Qty: Decimal; 91 92 WidthStrings: array[2] of Text; 93 HeightStrings: array[2] of Text; 94 LengthStrings: array[2] of Text; 95 96 Run: Record "OptiPack Run"; 97 os: OutStream; 98 VizUrl: Text; 99 VizHttp: HttpClient; 100 VizResp: HttpResponseMessage; 101 VizCntHdrs: HttpHeaders; 102 VizHtml: Text; 103 VizPage: Page "OptiPack Visualisation"; 104 begin 105 // Setup 106 if not Setup.FindFirst() then 107 Error('Open "OptiPack Setup" and click Create/Init, then fill URL and API key.'); 108 if (Setup."Pack URL" = '') or (Setup."Pack API Key" = '') then 109 Error('OptiPack Setup is incomplete. URL/API key missing.'); 110 111 // Collect items from this Sales Order 112 OrdersArr := OrdersArr; 113 OrderObj := OrderObj; 114 ItemsArr := ItemsArr; 115 116 SL.SetRange("Document Type", SL."Document Type"::Order); 117 SL.SetRange("Document No.", SalesHdr."No."); 118 SL.SetRange(Type, SL.Type::Item); 119 120 if SL.FindSet() then 121 repeat 122 Qty := SL.Quantity; 123 if Qty <= 0 then 124 continue; 125 126 WidthStrings[1] := 'Width'; 127 WidthStrings[2] := 'Breedte'; 128 HeightStrings[1] := 'Height'; 129 HeightStrings[2] := 'Hoogte'; 130 LengthStrings[1] := 'Length'; 131 LengthStrings[2] := 'Diepte'; 132 // Fetch dimensions from Item Attributes (supports EN + NL names) 133 if not TryGetDimFromAttributes(SL."No.", WidthStrings, W) then 134 W := 0; 135 if not TryGetDimFromAttributes(SL."No.", HeightStrings, H) then 136 H := 0; 137 if not TryGetDimFromAttributes(SL."No.", LengthStrings, L) then 138 L := 0; 139 140 MissingPerItem := ''; 141 if W = 0 then MissingPerItem += 'Width/Breedte '; 142 if H = 0 then MissingPerItem += 'Height/Hoogte '; 143 if L = 0 then MissingPerItem += 'Length/Diepte '; 144 145 if MissingPerItem <> '' then begin 146 if MissingTxt <> '' then MissingTxt += ''; 147 MissingTxt += StrSubstNo('Item %1 missing: %2', SL."No.", MissingPerItem); 148 end else begin 149 Clear(ItemObj); 150 ItemObj.Add('id', SL."No."); 151 ItemObj.Add('width', W); 152 ItemObj.Add('height', H); 153 ItemObj.Add('depth', L); // map Length/Diepte -> depth 154 ItemObj.Add('quantity', Qty); 155 ItemsArr.Add(ItemObj); 156 end; 157 until SL.Next() = 0; 158 159 if MissingTxt <> '' then 160 Error(MissingTxt); 161 if ItemsArr.Count() = 0 then 162 Error('No qualifying item lines with dimensions on Sales Order %1.', SalesHdr."No."); 163 164 // Build orders array 165 Clear(OrderObj); 166 OrderObj.Add('id', SalesHdr."No."); 167 OrderObj.Add('items', ItemsArr); 168 OrdersArr.Add(OrderObj); 169 170 // Build bins from OptiPack Boxes (Active only) 171 BinsArr := BinsArr; 172 Box.SetRange(Active, true); 173 if Box.FindSet() then 174 repeat 175 Clear(BinObj); 176 BinObj.Add('id', Box.Code); 177 BinObj.Add('width', Box.Width); 178 BinObj.Add('height', Box.Height); 179 BinObj.Add('depth', Box.Depth); 180 BinsArr.Add(BinObj); 181 until Box.Next() = 0 182 else 183 Error('No active OptiPack Boxes found. Open "OptiPack Boxes" and create at least one.'); 184 185 // Build payload 186 Clear(Payload); 187 Payload.Add('scenario_id', Setup."Scenario Id"); 188 Payload.Add('orders', OrdersArr); 189 Payload.Add('bins', BinsArr); 190 191 Payload.WriteTo(BodyTxt); 192 Cnt.WriteFrom(BodyTxt); 193 194 // Content headers 195 Cnt.GetHeaders(CntHdrs); 196 if CntHdrs.Contains('Content-Type') then CntHdrs.Remove('Content-Type'); 197 CntHdrs.Add('Content-Type', 'application/json'); 198 199 // Request headers 200 ReqHdrs := Http.DefaultRequestHeaders(); 201 if ReqHdrs.Contains('Accept') then ReqHdrs.Remove('Accept'); 202 if ReqHdrs.Contains('x-api-key') then ReqHdrs.Remove('x-api-key'); 203 ReqHdrs.Add('Accept', 'application/json'); 204 ReqHdrs.Add('x-api-key', Setup."Pack API Key"); 205 206 Http.Timeout := 120000; 207 if not Http.Post(Setup."Pack URL", Cnt, Resp) then 208 Error('HTTP POST failed.'); 209 210 Resp.Content().ReadAs(BodyTxt); 211 if not Resp.IsSuccessStatusCode() then 212 Error('OptiPack error %1: %2', Resp.HttpStatusCode(), CopyStr(BodyTxt, 1, 4000)); 213 214 Message('OptiPack Response:%1%2', '', CopyStr(BodyTxt, 1, 4000)); 215 // 1) Parse response_id (or request_id) from JSON 216 if Root.ReadFrom(BodyTxt) then begin 217 if Root.Get('_id', Tok) and Tok.IsValue() then 218 ResponseId := Tok.AsValue().AsText() 219 else if Root.Get('request_id', Tok) and Tok.IsValue() then 220 ResponseId := Tok.AsValue().AsText(); 221 end; 222 223 if ResponseId <> '' then begin 224 Run.Init(); 225 Run."Sales Order No." := SalesHdr."No."; 226 Run."Response Id" := CopyStr(ResponseId, 1, 100); 227 Run."Created At" := CurrentDateTime(); 228 Run."Raw Response".CreateOutStream(os); 229 os.WriteText(CopyStr(BodyTxt, 1, MaxStrLen(BodyTxt))); 230 Run.Insert(); 231 232 COMMIT; 233 234 VizUrl := StrSubstNo('https://optiapp.api.optioryx.com/visualisation/interactive/%1/0/0?offline=false', ResponseId); 235 236 VizHttp.DefaultRequestHeaders().Add('Accept', 'text/html'); 237 VizHttp.DefaultRequestHeaders().Add('x-api-key', Setup."Pack API Key"); 238 239 if not VizHttp.Get(VizUrl, VizResp) then begin 240 Error('HTTP GET failed for visualisation.'); 241 end; 242 243 VizResp.Content().ReadAs(VizHtml); 244 245 if not VizResp.IsSuccessStatusCode() then 246 Error('Visualisation error %1: %2', VizResp.HttpStatusCode(), CopyStr(VizHtml, 1, 4000)); 247 248 // 5) Show in the viewer page 249 VizPage.LoadHtml(VizHtml); 250 VizPage.RunModal(); 251 end else 252 Message('Pack call succeeded but no response id was found. Response:%1%2', '', CopyStr(BodyTxt, 1, 4000)); 253 end; 254}

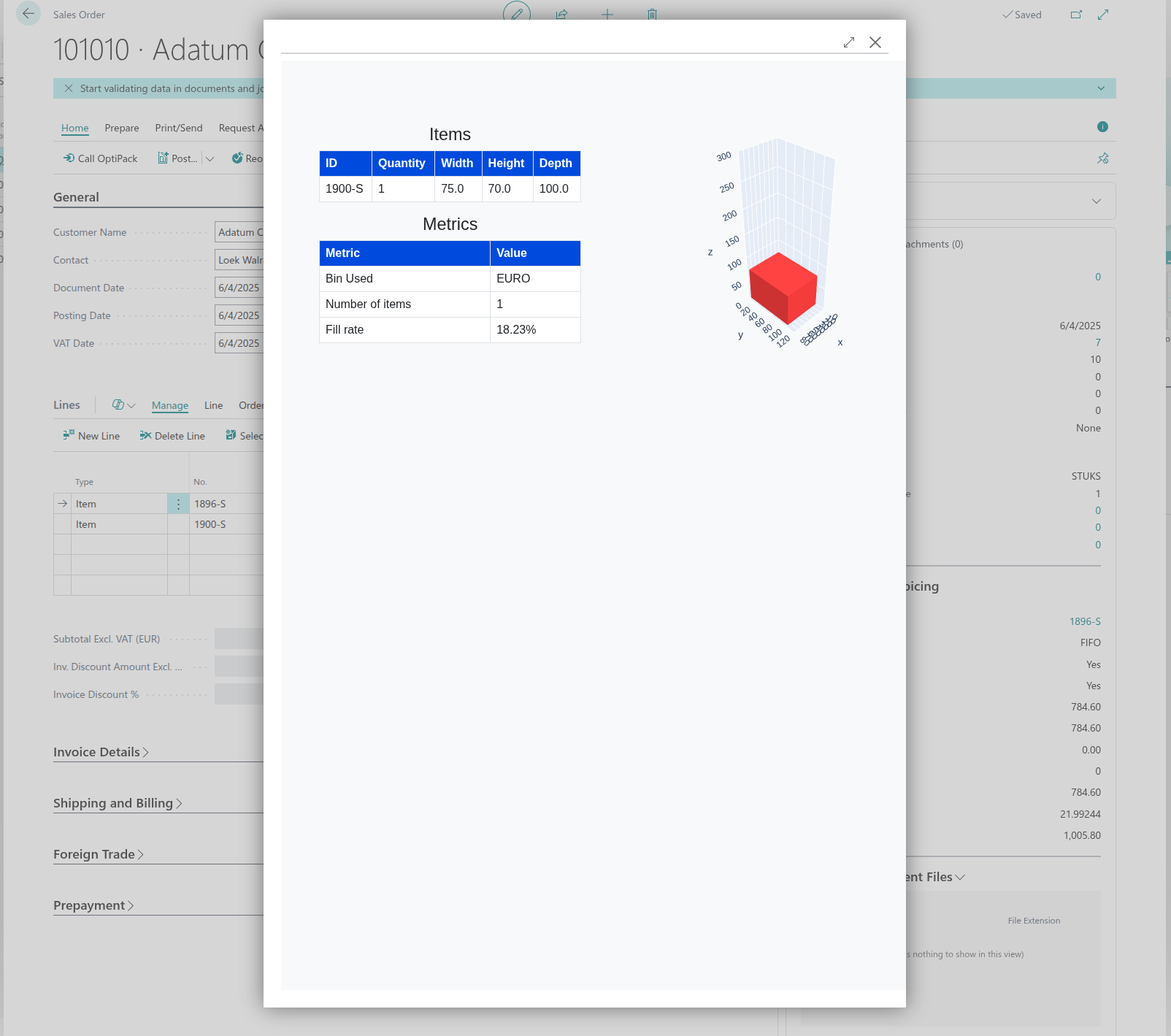

Visualising the packing result in BC

The OptiPack API contains an endpoint that returns HTML with an interactive visualisation that can be embedded in another system. We will integrate this visualisation in Business Central as a final step. We first create a page:

1page 50128 "OptiPack Visualisation" 2{ 3 PageType = Card; 4 ApplicationArea = All; 5 Caption = 'OptiPack Visualisation'; 6 7 layout 8 { 9 area(content) 10 { 11 usercontrol(Viewer; "OptiPack.HtmlViewer") 12 { 13 ApplicationArea = All; 14 15 trigger Ready() 16 begin 17 IsReady := true; 18 if HtmlToLoad <> '' then begin 19 CurrPage.Viewer.SetHtml(HtmlToLoad); 20 // Optional: clear buffer after push 21 // HtmlToLoad := ''; 22 end; 23 end; 24 } 25 } 26 } 27 28 var 29 HtmlToLoad: Text; 30 IsReady: Boolean; 31 32 /// Call this BEFORE or AFTER the page opens; it buffers until the add-in is ready. 33 procedure LoadHtml(Html: Text) 34 begin 35 HtmlToLoad := Html; 36 if IsReady then 37 CurrPage.Viewer.SetHtml(HtmlToLoad); 38 end; 39 40 trigger OnOpenPage() 41 begin 42 // in case Ready already fired quickly on some clients, the buffer logic still works 43 end; 44}

Which contains the following HTMLViewer:

1namespace DefaultPublisher.AL; 2 3controladdin "OptiPack.HtmlViewer" 4{ 5 RequestedHeight = 700; 6 RequestedWidth = 1000; 7 MinimumHeight = 300; 8 MinimumWidth = 600; 9 VerticalStretch = true; 10 HorizontalStretch = true; 11 12 Scripts = 'scripts/optipackviewer.js'; // add this file to your project 13 StartupScript = 'scripts/optipackviewer.js'; 14 15 event Ready(); 16 17 procedure SetHtml(Html: Text); 18}

This embeds the HTML returned by our API in a page using this simple javascript script:

1(function () { 2 var container, iframe; 3 4 function ensure() { 5 // BC injects <div id="controlAddIn"> as the host root 6 container = document.getElementById('controlAddIn'); 7 if (!container) { 8 // very defensive: if not yet present, retry soon 9 setTimeout(ensure, 10); 10 return; 11 } 12 container.style.margin = '0'; 13 container.style.padding = '0'; 14 container.style.width = '100%'; 15 container.style.height = '100%'; 16 container.style.overflow = 'hidden'; 17 18 if (!iframe) { 19 iframe = document.createElement('iframe'); 20 iframe.setAttribute('title', 'OptiPack Visualisation'); 21 iframe.style.border = '0'; 22 iframe.style.width = '100%'; 23 iframe.style.height = '100%'; // Fill add-in 24 iframe.style.display = 'block'; 25 container.appendChild(iframe); 26 27 // Signal BC that the add-in is ready 28 if (Microsoft && Microsoft.Dynamics && Microsoft.Dynamics.NAV) { 29 Microsoft.Dynamics.NAV.InvokeExtensibilityMethod('Ready', []); 30 } 31 } 32 } 33 34 // Write full HTML string into the iframe document 35 function writeHtmlToIframe(html) { 36 ensure(); 37 if (!iframe) return; 38 39 // Inject CSS to guarantee the viz has measurable height 40 var headBoost = 41 '<style>html,body{height:100%;margin:0;padding:0;overflow:hidden;} ' + 42 '#root,#app,.container,.visualization-container{height:100% !important;} ' + 43 'iframe,canvas,svg{max-width:100%;}</style>'; 44 45 var doc = iframe.contentWindow.document; 46 doc.open(); 47 // Prepend our boost style before user HTML 48 doc.write(headBoost + (html || '')); 49 doc.close(); 50 51 // If content relies on layout after load, try a couple of resizes 52 try { 53 var tryResize = function () { 54 var body = doc.body, de = doc.documentElement; 55 var h = Math.max( 56 body.scrollHeight, body.offsetHeight, 57 de.clientHeight, de.scrollHeight, de.offsetHeight 58 ); 59 // If parent add-in is stretching, keep iframe at 100%; if zero, fallback to content height 60 if (container && container.clientHeight === 0 && h > 0) { 61 iframe.style.height = h + 'px'; 62 } else { 63 iframe.style.height = '100%'; 64 } 65 }; 66 setTimeout(tryResize, 50); 67 setTimeout(tryResize, 300); 68 window.addEventListener('resize', tryResize); 69 } catch (e) { 70 // ignore 71 } 72 } 73 74 // Expose to AL 75 window.SetHtml = function (html) { 76 writeHtmlToIframe(String(html || '')); 77 }; 78 79 // Initial setup 80 ensure(); 81})();

The result is the following:

Field mapping (recap)

| OptiPack JSON | Business Central source |

|---|---|

orders[].id | Sales Order No. (Sales Header."No.") or Warehouse Shipment No. (if you pack per shipment) |

orders[].items[].id | Item No. (Sales Line."No.") |

orders[].items[].quantity | Sales Line.Quantity (or Qty. to Ship if partials) |

orders[].items[].width/height/depth | Item Attributes (e.g., Width/Breedte, Height/Hoogte, Length/Diepte) or custom fields |

orders[].items[].weight (optional) | Item Attribute or Unit Weight field if you keep one |

orders[].items[].allowed_orientations / fragile flags (optional) | Item Attributes / custom flags |

bins[].id | OptiPack Box Code (OptiPack Box.Code) |

bins[].width/height/depth | OptiPack Box.Width/Height/Depth |

other bins[] constraints (max weight, stack limits, etc.) | Add columns to OptiPack Box and pass through |

scenario_id | OptiPack Setup."Scenario Id" |

Where to call OptiPack in BC?

Pick a path (teams usually start with A, then evolve to B):

A) After Shipment is ready (simplest POC)

- Users create Warehouse Shipments as usual.

- From Sales Order or Warehouse Shipment, call OptiPack with the order’s lines (Item No., quantity, dimensions/weight).

- Show the packing plan + visualization to the packer.

Pros: Very low friction, minimal dev.

Cons: You still pack manually in BC (unless you write back as packages).

B) Shipment-centric with package write-back

- When a Warehouse Shipment is ready for packing, collect its lines → build one OptiPack

order. - Call OptiPack; on success, create BC Packages/Lines (or your custom Package tables) per OptiPack result.

- Print labels / hand over to your carrier add-on.

Pros: Produces system packages you can label/ship.

Cons: Requires a small “write-back” layer (custom page/table or a package add-on).

Note: Cartonization does not depend on Bin Code allocation. You only need the order’s items, quantities, and physical attributes, plus your box catalog.

Persisting the results (BC)

- Store the run header:

OptiPack Runwith Sales Order No., response/request id, timestamp, raw payload/response (Blob). - Write system packages (optional):

- If you already use a packing add-on, convert OptiPack bins → add-on’s package tables.

- If not, add a simple “OptiPack Package” table (Header + Lines) and render it on a “Packing Worksheet” page for label printing.

- Keep traceability: Save the

response_id, selected box per order, total cubic fill, and any rule flags (e.g., “fragile kept upright”) for KPIs.

Setup checklist (BC)

Read permissions

Sales Header/Line,Item,Item Attribute / Attribute Value / Mapping.

Write permissions

OptiPack Setup,OptiPack Box,OptiPack Run(and your optional Package tables).

Data quality

- Item Attributes for Width/Height/Length (and Weight if used) consistently maintained.

- Units are consistent between items and boxes (cm/mm/in). If they aren’t, normalize before sending.

Connectivity & security

- Allow outbound HTTPS to

optiapp.api.optioryx.com. - Keep API key in Masked field; restrict access to OptiPack Setup.

Feature toggles

- Add

OptiPack EnabledandShow Visualisationbooleans in Setup so ops can bypass quickly.

Box catalog

- Maintain active boxes in OptiPack Boxes. Add optional columns you need (see our API docs for possible attributes and constraints our algorithm supports).

Additional Tips & Tricks

Reliability & monitoring

- Retry with exponential backoff on HTTP 429/5xx.

- Set a sensible timeout; on timeout, fall back to current manual packing.

- Log: order/shipment id, request hash, HTTP code, response id, decision (optimized vs fallback).

Idempotency

- Use the BC order/shipment no. + a timestamp as a run key.

- If you re-run, upsert the OptiPack Run and overwrite packages only when you confirm.

Performance

- Build the JSON directly from

Sales Linejoined to Attribute Mappings (filter by current order/shipment). - Validate all required attributes in one pass; present a single error list to fix master data.

Data fidelity

- If an item has multiple UoMs, ensure the dimensions match the selling UoM (e.g., pack-size vs each).

- For sets/kits, expand to component items with physical dimensions before sending.

UX

- Show the interactive visualization inline (your control add-in) and provide a quick “Copy result summary” action: chosen box, fill rate, #boxes, weight.

Governance

- Keep an eye on box creep: archive inactive sizes so the optimizer searches only real, stocked cartons.

- Add a simple A/B toggle: operator can compare OptiPack result with “default box” to build trust.